WHAT IS CAMISHA?

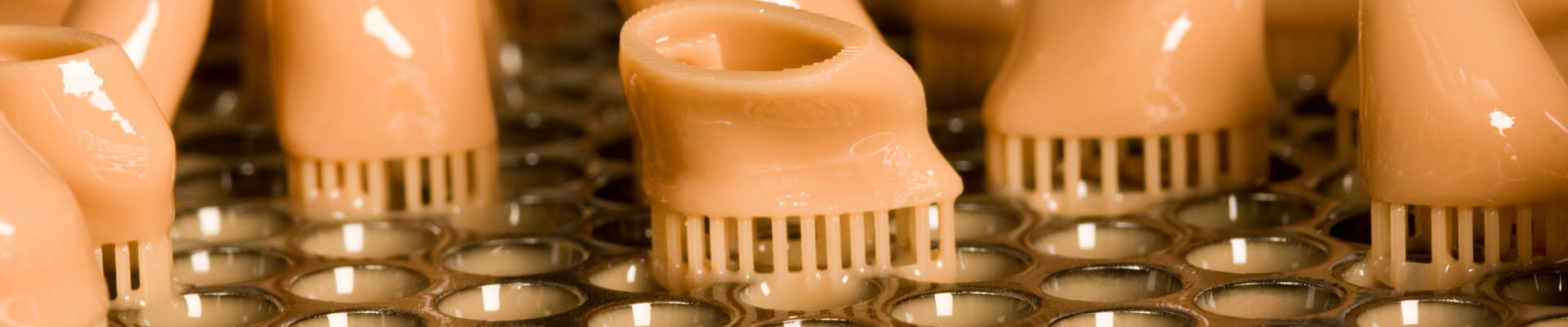

CAMISHA is our award winning method of manufacturing individual hearing aid shells, earmolds and ear-pieces.

CAMISHA stands for Computer Aided Manufacturing of Individual Shells for Hearing Aids. It uses laser technology to make an impression of the hearing aid user’s ear canal and turns this data into a 3D computer model. This is then used as a basis for the manufacturing of individual shells and earmolds that fit the user’s ear canal exactly.